Ex cable glands are designed for use on electrical equipment in hazardous areas in accordance with EN 60079-0, EN 60079-1 and EN 60079-7. HUMMEL cable glands offer explosion protection for the types of protection:

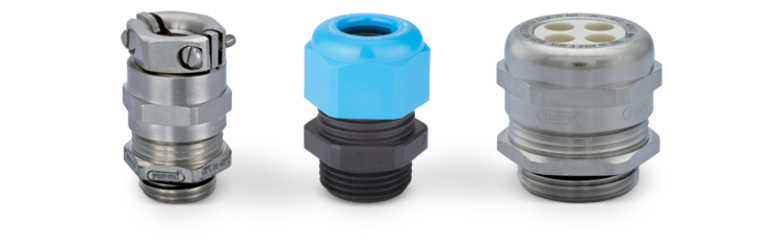

HUMMEL offers Ex cable glands in plastic (glass fibre reinforced polyamide), brass and stainless steel. The range includes glands with metric, PG and NPT threads. In addition to the standard sealing inserts, there are also inserts for flat cables or multi-inserts for the insertion of several cables with one cable gland. Ex cable glands with EMC protection are also available.

Today, we likely live in two worlds when it comes to approvals for explosion proof cable glands. On one hand there is ATEX (IECEx) mainly found in Europe, on the other hand there is the UL class/div world, widely spread and well known in North America, especially in the United States.

There may be good reasons for either using ATEX or UL as both schemes are well established in its markets. Nevertheless, more and more customers require only one single cable gland that could be used globally, thus reducing supply chain efforts as well as time and cost for market specific production and approvals.

As of today, this is still the biggest challenge when looking for the perfect cable gland as UL class/div requires different test parameters than ATEX, with its own test methods for impact, and a 30 bar static pressure test that may require a different design making it almost impossible to also include EMC protection.

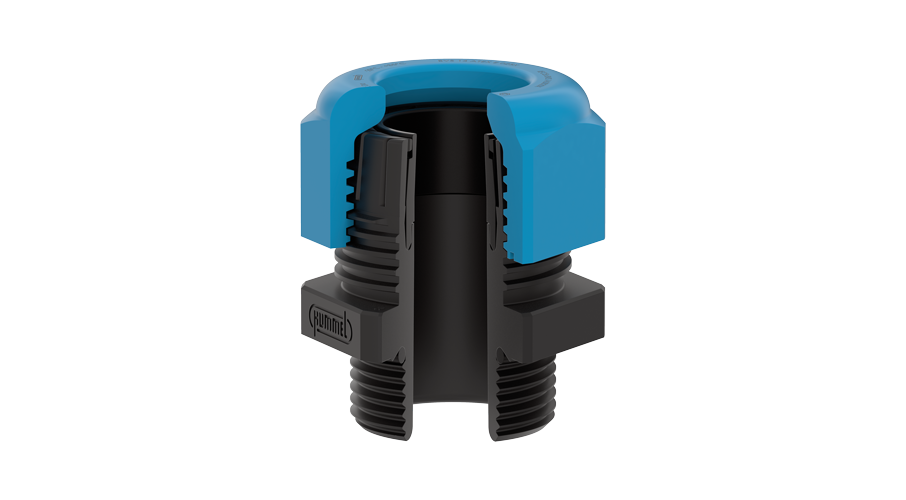

Along with outstanding quality, the market demands economical and smart cable gland solutions. This means a small footprint and EMC protection as well as a simple assembly concept as this saves time and cost. HUMMEL is facing a global market demand for one product covering both, ATEX / IECEx, and UL class/zone approvals. With HUMMEL's new “Global Gland”, an HSK-M-Ex series user has the opportunity to drastically reduce its supply chain and engineering efforts by meeting UL Class/div and the ATEX requirements with only one single solution. Along with the existing ATEX / IECEx approval the HSK-M-Ex series is now certified cCSAus for Class / Zone which allows using the Glands also in Class I and II Division 2 applications after NEC codes 501 and 502.

4 Steps to get your application ready for UL class/div: